The Barrel Leg: Why It’s the Most Flattering Denim Cut of Fall 2025

The post-skinny era introduced volume, but the barrel leg perfected it. We break down the new architectural fit, celebrated by stars like Katie Holmes, and show you how to ensur…

Mastering Denim Couture: How to Wear Embellishments and Crystals for Holiday Style

Forget traditional silk and velvet. This holiday season, denim is stepping into the spotlight as the ultimate fabric for glamour. Learn how to transform your jeans into a collec…

Low-Rise, Reimagined: How Gap is Bringing Back the Y2K Waistline

Low-rise is back, but it’s not the uncomfortable, universally reviled trend of the early 2000s. We break down Gap’s strategic revival and show how the custom approach makes this…

Wool Denim: Your F/W Game Changer for Thermoregulation and Comfort

Say goodbye to stiff, cold denim in the winter. We break down the technical genius of wool denim blends—a fabric that keeps you warm, dry, and stylish while offering superior lo…

The Modern Canadian Tuxedo: Why Matching Denim Sets Are Back (and Sharper)

The infamous denim-on-denim look has moved beyond novelty. Discover how matching denim sets are reinventing themselves as a sleek, coordinated wardrobe solution.

Dark Indigo is the New Black: Shopping the Rich Wash Trend for F/W 2025

Black denim is taking a back seat. This season, rich, inky dark indigo is the color of elegance, providing a versatile foundation for both casual and formal wear.

The Soft Revolution: Why Premium Finishes and Soft-Touch Denim are Key to Fall Style

Denim is getting a high-end makeover. Learn how the pursuit of the ‘feel-good’ fit has led brands to prioritize soft-touch fabrics and premium finishes over raw ruggedness.

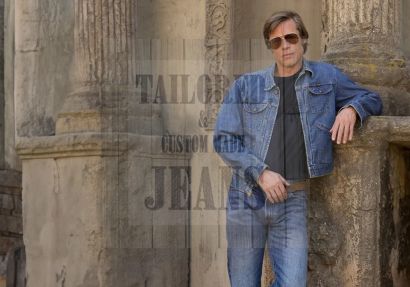

The High-Low Look: How to Style an Oversize Denim Jacket with Tailored Pants

The old rules of tailoring are out. Discover how to create the season’s chicest proportional mash-up by pairing a rugged, oversized denim jacket with sleek, tailored trousers.

Tech Fleece Denim: Built for Winter with Windproof and Heat-Retaining Technology

Jeans that are genuinely warm? Discover how specialized technical fabrics and custom fit are turning classic denim into an essential piece of cold-weather armor.

Texture Mash-up: Pairing Velvet and Corduroy with Denim for Fall 2025

Winter demands warmth and decadence. Learn the simple secrets to mixing high-pile fabrics like velvet and corduroy with your durable denim for a sophisticated and cozy seasonal …

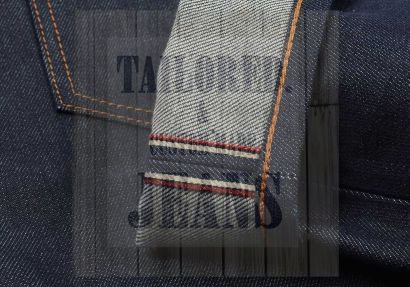

ABOUT US

We are the global standard in custom-fit denim, meticulously crafted for unparalleled comfort and style. With decades of expertise, our commitment to precision tailoring and sustainable practices ensures every pair reflects our dedication to quality and your unique fit. Discover the perfect jeans, Making & Delivering Custom Jeans in USA and worldwide.

Tailored-Jeans.com: Crafting exceptional denim since 1996 in United States with an unwavering commitment to fit and quality. Discover our legacy.